[Expert Views] Solutions in Patents: How to Prevent Thermal Runaway of Lithium Batteries from Cell, Module and BMS (Part 2)

As electric vehicles have become more and more popular, fire accidents occurred within EVs are occasionally reported in the news. If we take a closer look at photos taken during these fire accidents, such photos often reveal that damages to the EVs are more severe than that seen with conventional engine vehicles. Mostly, they are caused by the power source of the EVs – Lithium batteries. Lithium batteries contain highly flammable lithium metal and organic materials. When the battery catches fire, it keeps burning at high temperatures, thus making it difficult to be put out, or even causing an explosion. Such phenomenon is called thermal runaway. Since lithium batteries have be widely used in EVs, thermal runaway has become a critical problem for the industry to solve to improve driving safety. In previous article, solutions in patents from the aspect of cell manufacturing have been discussed. In this article, related patents of battery module design will be analyzed.

Technologies of battery module design

The voltage of single lithium battery cell is within the range of 3.2V to 3.7V, and capacity of 2Ah to 5Ah. As the power source of EVs, multiple battery cells are connected to achieve a desired voltage and capacity. Taking Tesla MODEL S as an example, its battery capacity is 85kWh, including 7,104 cells

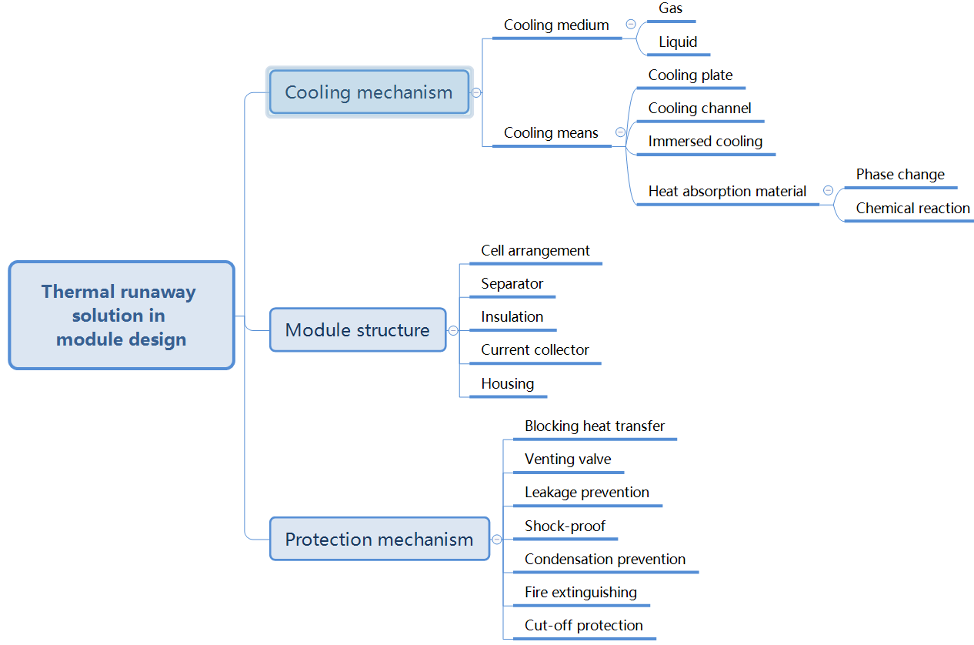

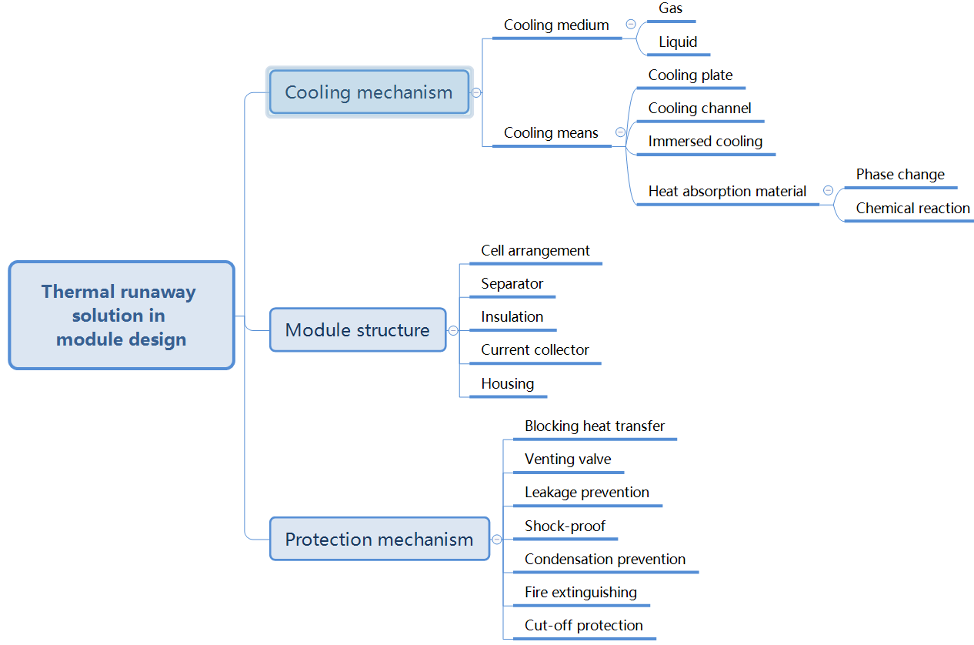

[1]. When more cells are connected, the risk of thermal runaway increases. Therefore, mechanisms to prevent such hazard are required for the design of battery modules. Also, when thermal runaway occurs in one cell of the module, other cells must be protected to prevent chain reaction. Fig. 1 shows technologies able to prevent thermal runaway in battery modules, including cooling mechanisms, improvements to the module structure, and various protection mechanisms. Detailed solutions will be described below.

Fig. 1 Technologies of preventing thermal runaway in battery modules

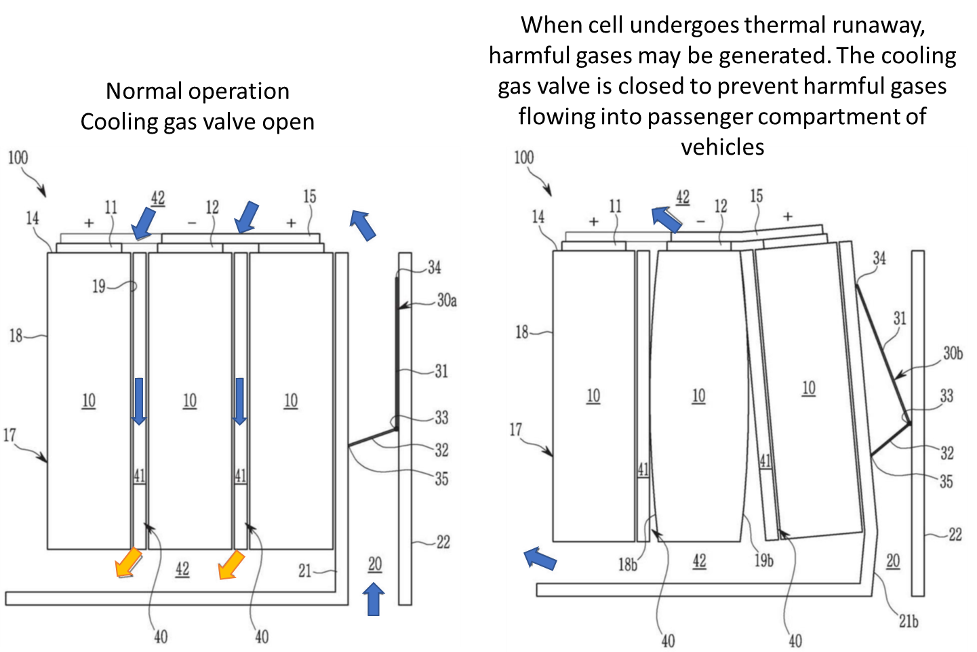

Cooling mechanism – Cooling medium

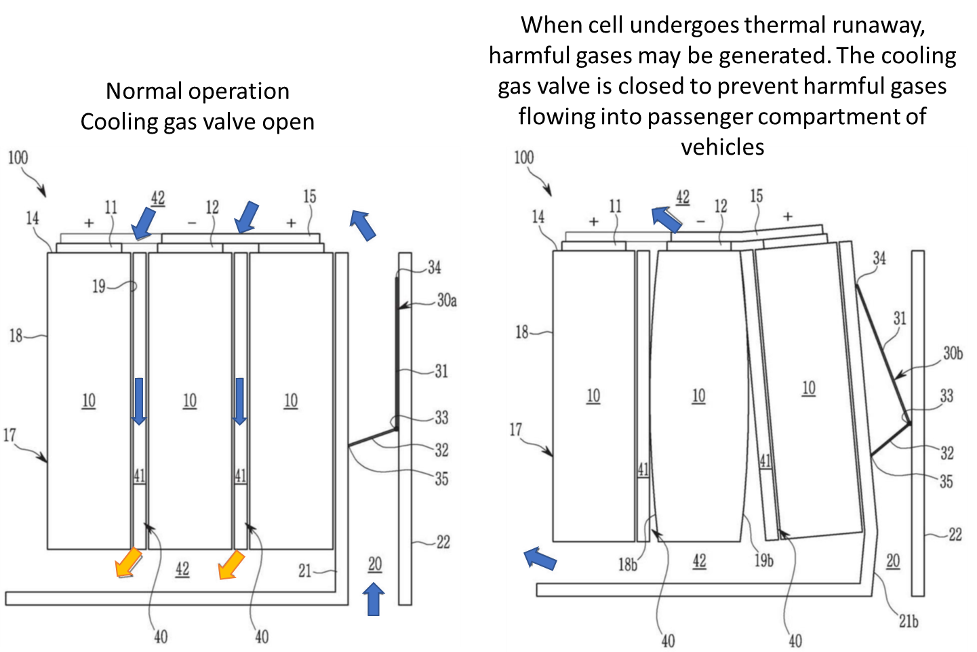

Thermal energy is generated during the charging and discharging processes of batteries. The most common cause of thermal runaway in battery modules is localized in battery overheating. Therefore, how to dissipate heat evenly and efficiently is the most important issue addressed when designing battery modules. According to its cooling medium, the heat dispassion may be a gas-cooling type or a liquid-cooling type, such as low-temperature air or cooling water. Taking Samsung SDI’s patent US10340566 as an example, low-temperature air pathways are employed in EV battery modules to promote heat dispassion. Furthermore, when thermal runaway occurs in one cell and the cell releases harmful gases, the cooling gas valve is closed to prevent harmful gases flowing into passenger compartments of vehicles, as shown in Fig. 2 .

Fig. 2 Drawings of Samsung SDI’s patent US10340566

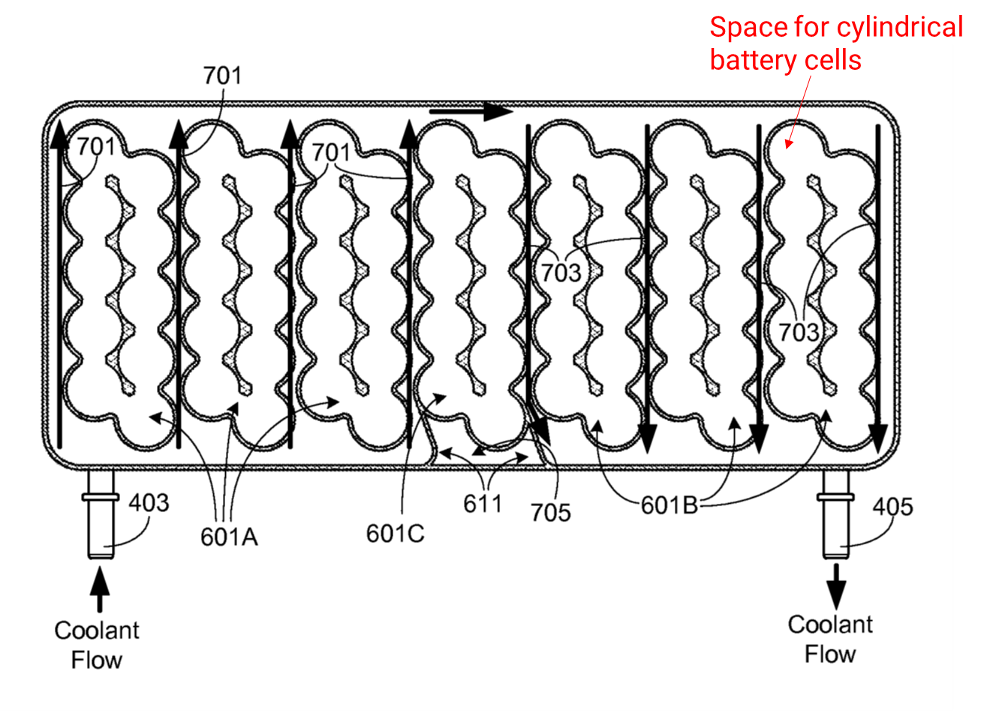

Cooling mechanism – Cooling means – Cooling channel

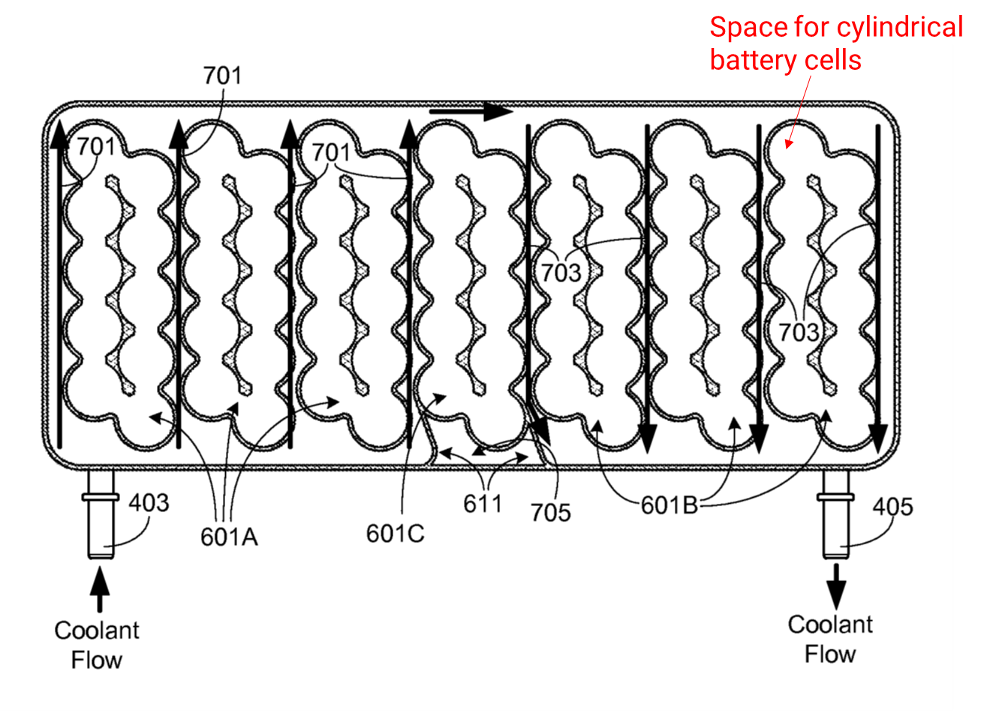

The most common cooling means is cooling plates that have high thermal conductivity in battery modules. Thermal energy generated by batteries is conducted by the cooling plates and dissipated toward the external environment. In EVs, cooling channels are often used to dissipate heat more effectively, e.g., the circulating system of cooling water. Taking Tesla’s patent US8647763 as an example, a battery coolant jacket is provided for cylindrical battery cells. The coolant jacket maximizes the thermal contact area of each cell and the coolant, while still electrically isolating the cells from each other as well as the coolant, as shown in Fig. 3.

Fig. 3 Drawing of Tesla’s patent US8647763

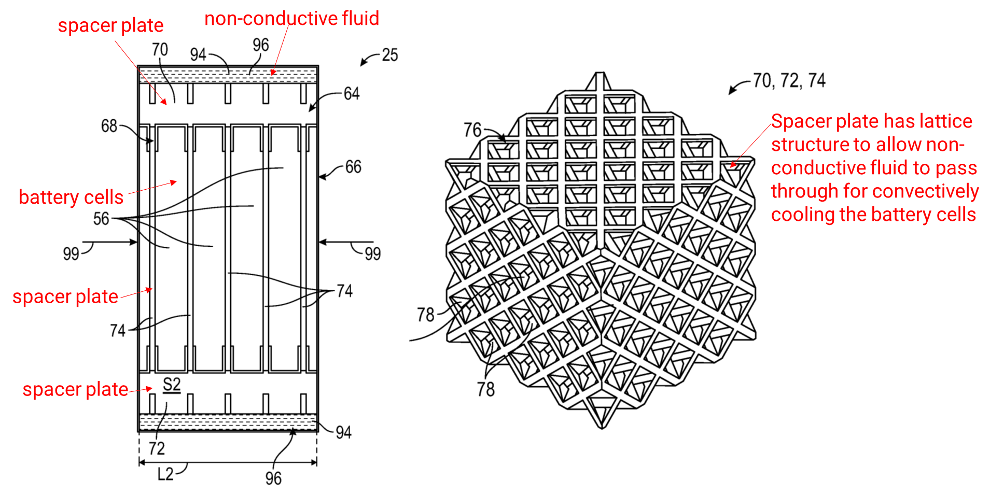

Cooling mechanism – Cooling means – Immersed cooling

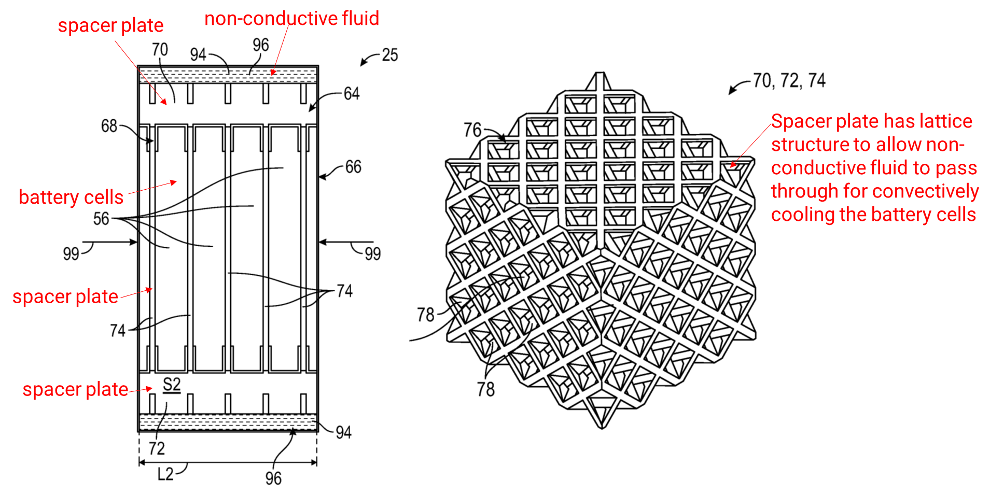

Besides cooling plates and cooling channels, there are also companies developing an immersed cooling technology, where batteries are immersed directly in a non-conductive cooling liquid to increase the heat transfer rate. Taking Ford’s patent US20220045388 as an example, compressible spacer plates having lattice structures are used in a battery module. A non-conductive (i.e., dielectric) fluid is received and communicated inside the battery module. The lattice structures of spacer plates allow the non-conductive fluid to pass through for convectively cooling the battery cells, as shown in Fig. 4.

Fig. 4 Drawing of Ford’s patent US20220045388

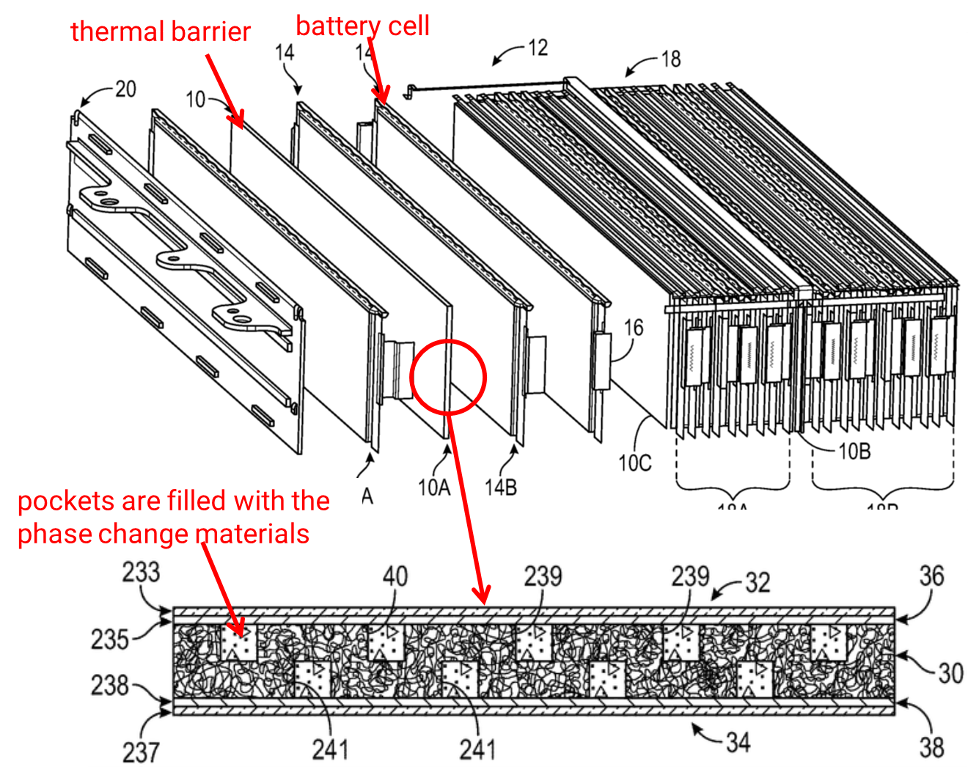

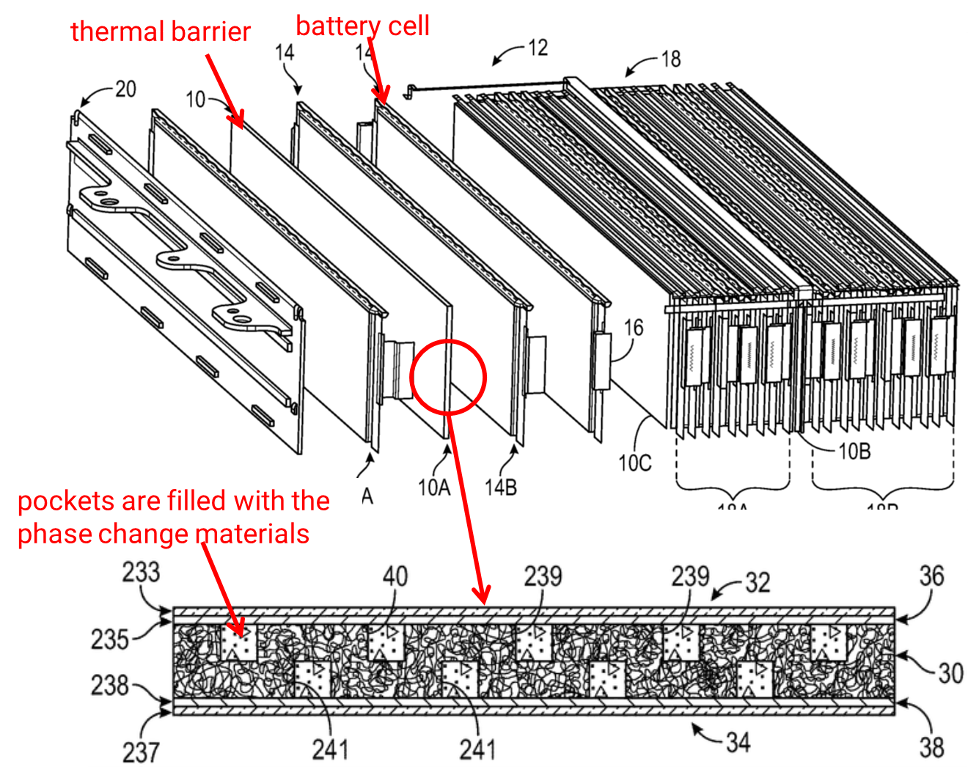

Cooling mechanism – Cooling means - Heat absorption materials

Heat absorption materials can also be used to cool battery cells, including phase change materials and heat absorbing chemical reactions. Taking GM’s patent US20210104793 as an example, thermal barriers are disposed between pouch-type battery cells. Each thermal battier has multiple pockets that are filled with phase change materials, as shown in Fig. 5. When the temperature of a battery cell increases, the phase change materials undergo phase change and absorb thermal energy to prevent the temperature rising of other cells. Besides phase change materials, materials that absorb heat when undergoing chemical reactions can achieve the same purpose.

Fig. 5 Drawing of GM’s patent US20210104793

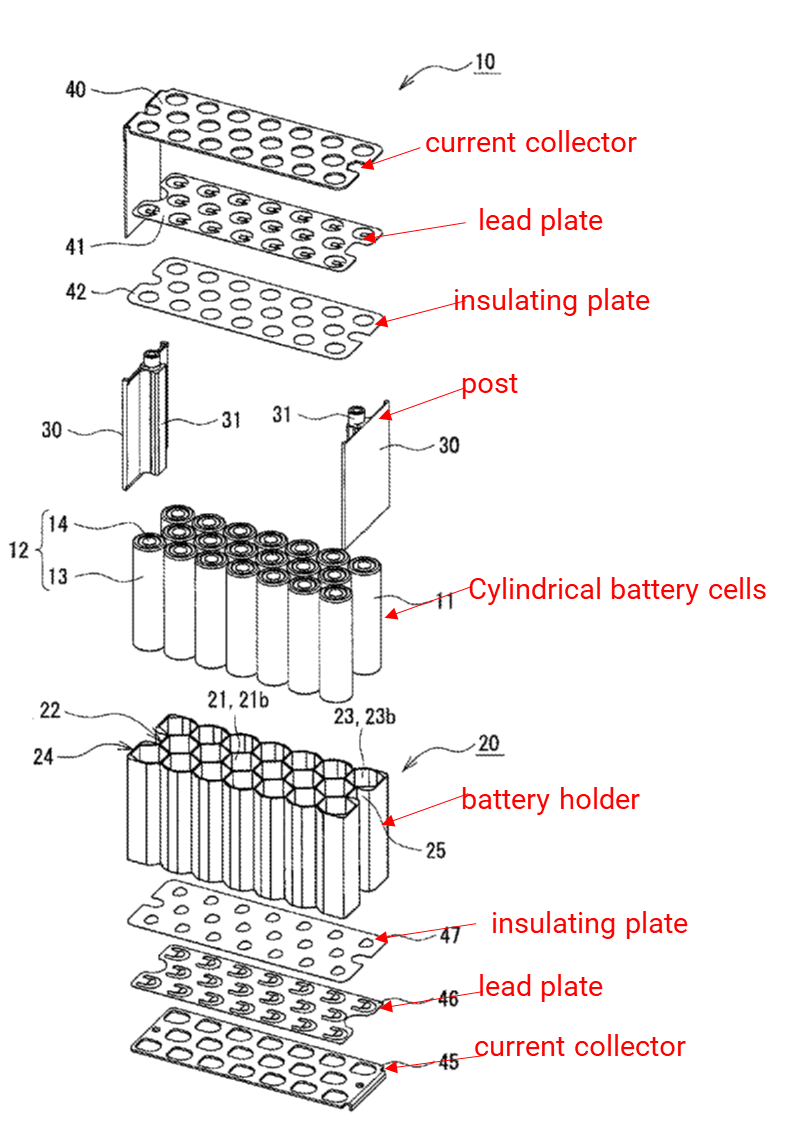

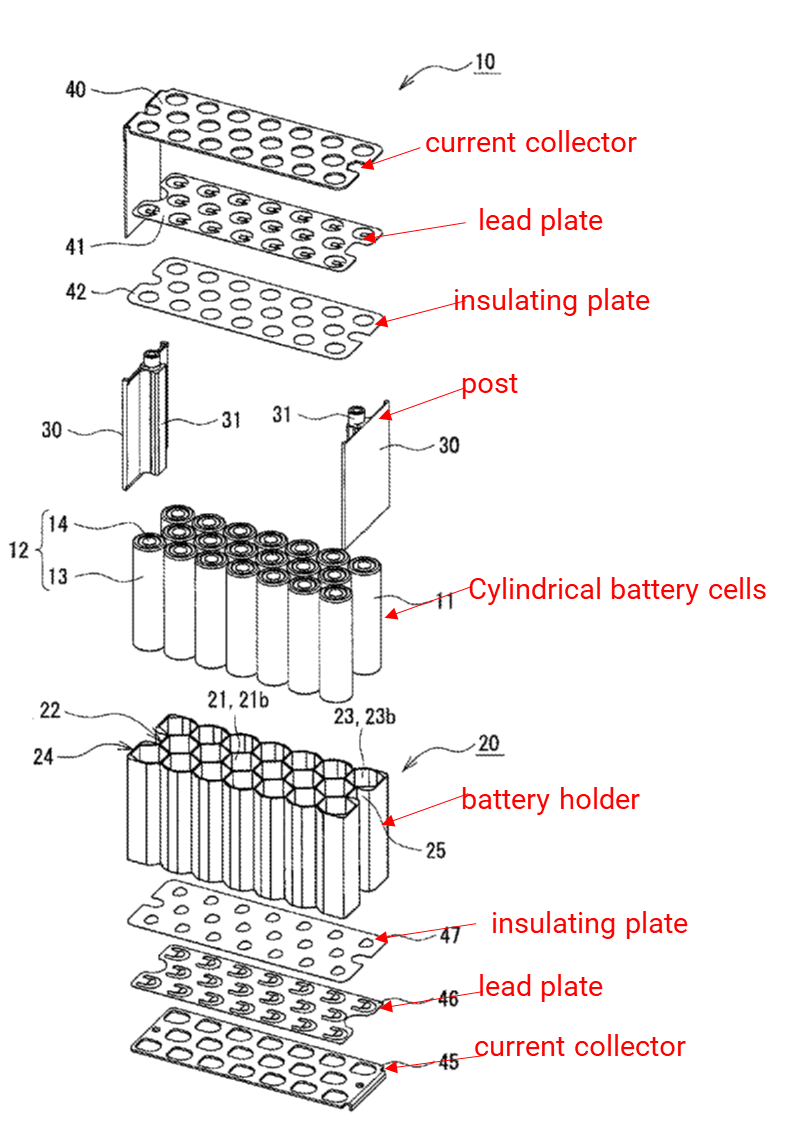

Module structure

A battery module structure includes separators, current collectors and outer cases to electrically connect and fix multiple cells. The design purpose of module structure is to increase energy density, heat dissipation, mechanical strength, and prevent short circuit. Taking Panasonic’s patent US10693112 as an example, a battery holder having a plurality of heptagonal tubular holes are used to accommodate cylindrical cells and increase the mechanical strength and heat dissipation of battery modules, as shown in Fig. 6.

Fig. 6 Drawing of Panasonic’s patent US10693112

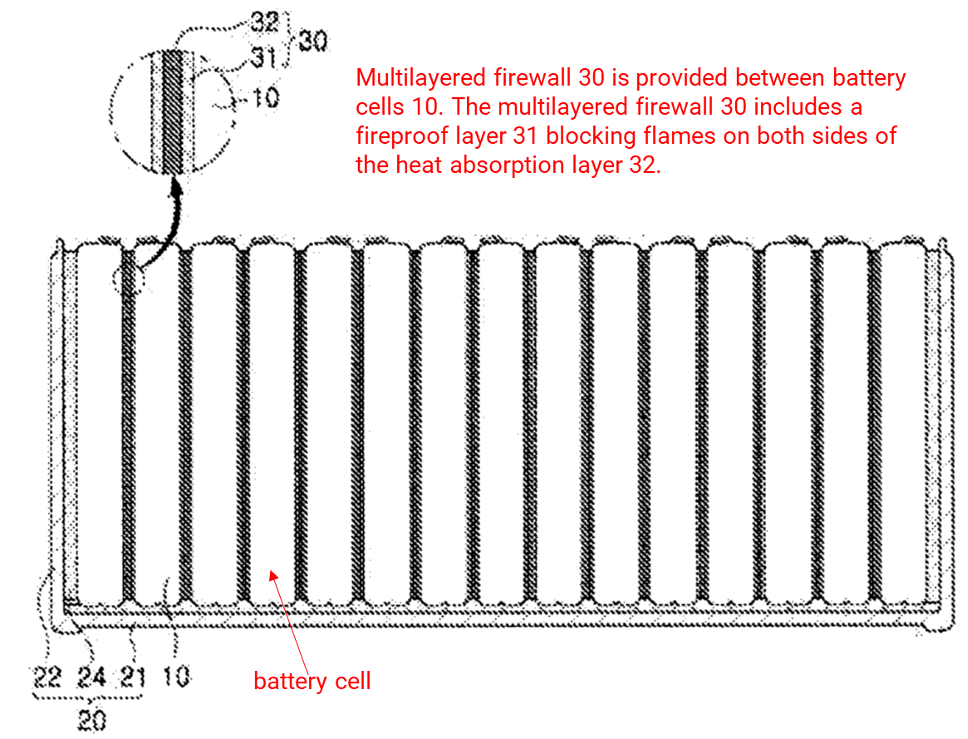

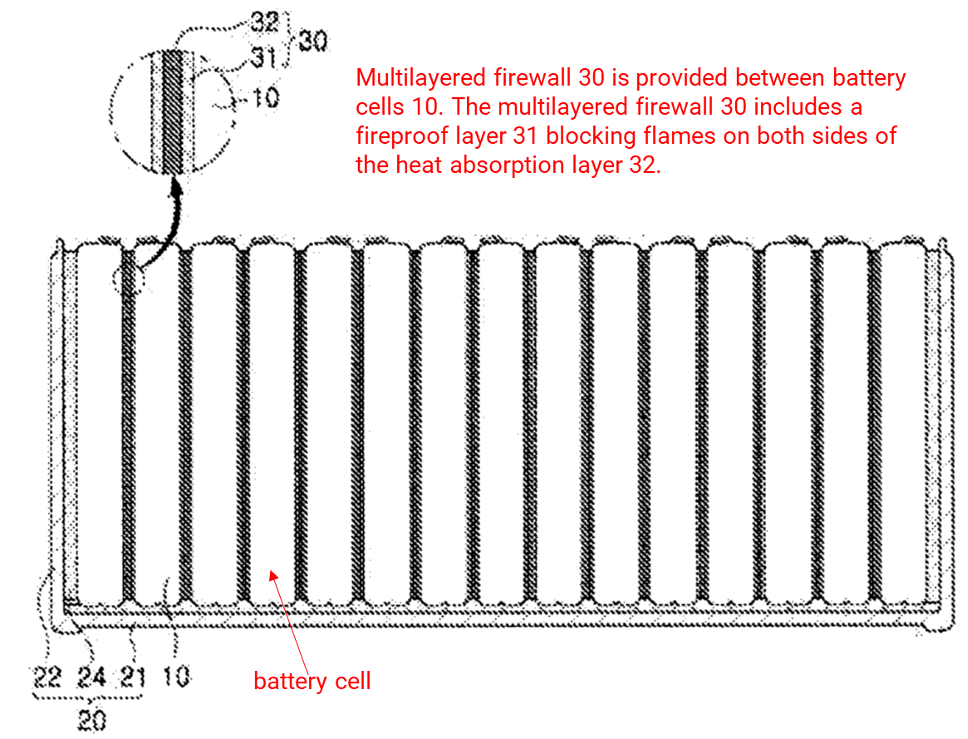

Protection mechanism – Blocking heat transfer

When thermal runaway occurs in one battery cell, heat transfer to adjacent cells must be prevented. Taking SK Innovation’s patent US20220037715 as an example, a multilayered firewall is provided between battery cells, as shown in Fig. 7. The multilayered firewall includes a fireproof layer blocking flames on both sides of a heat absorption layer.

Fig. 7 Drawing of SK Innovation’s patent US2022003771

Protection mechanism – Venting valve, leakage prevention, shock-proof, condensation prevention

Venting valve: As mentioned previously, when thermal runaway occurs, battery cells release hazardous gases, venting holes are required for the cells. Similarly, battery modules also have venting holes to allow the removal of hazardous gases.

Leakage prevention: In the case of batteries having liquid electrolyte, leakage occurs when the battery is punched. The leaking electrolyte must be immediately removed to prevent a short circuit from happening.

Condensation prevention: When the ambient temperature changes, condensation occurs inside the battery module, possibly causing a short circuit. Therefore, a condensation prevention mechanism may be considered for the design of battery modules. Taking GM’s patent US20210159473 as an example, a water condensation mitigation system for a battery pack is provided. The system includes a pressure valve mounted at the housing of the battery pack. When the ambient temperature or the pressure changes, the pressure valve opens to reduce the relative humidity inside the battery pack and balance the pressure within the battery pack with ambient pressure.

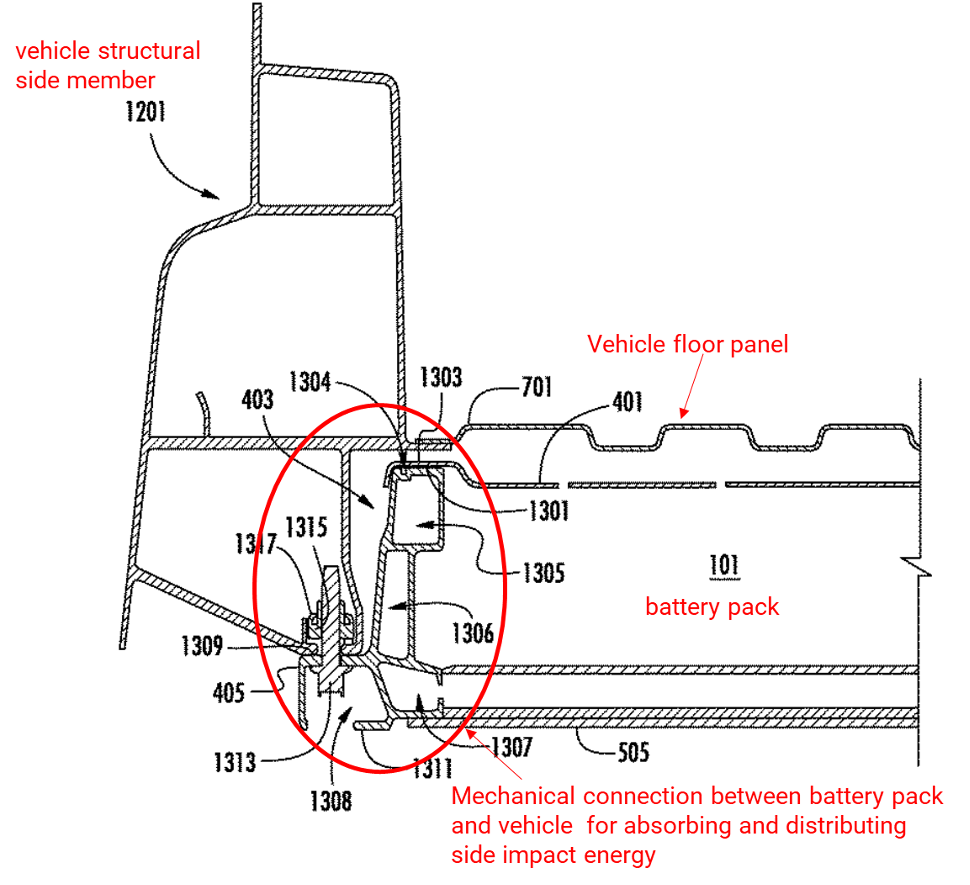

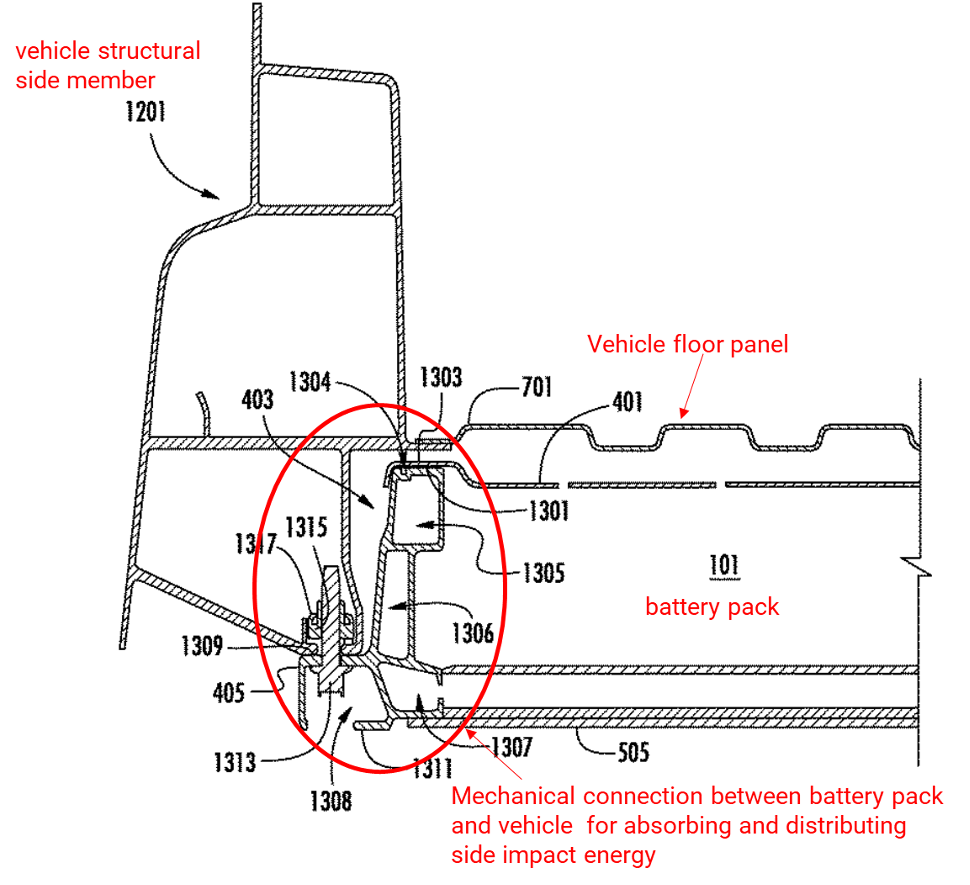

Shock-proof: Battery modules for EVs require shock-proof mechanism to reduce the risk of short circuit or disconnection. Taking Tesla’s patent US10780767 as an example, as shown in Fig. 8, a mechanical connection between the battery pack and vehicle is provided. The mechanical connection absorbs and distributes side impact energy from the vehicle to protect the battery pack.

Fig. 8 Drawing of Tesla’s patent US10780767

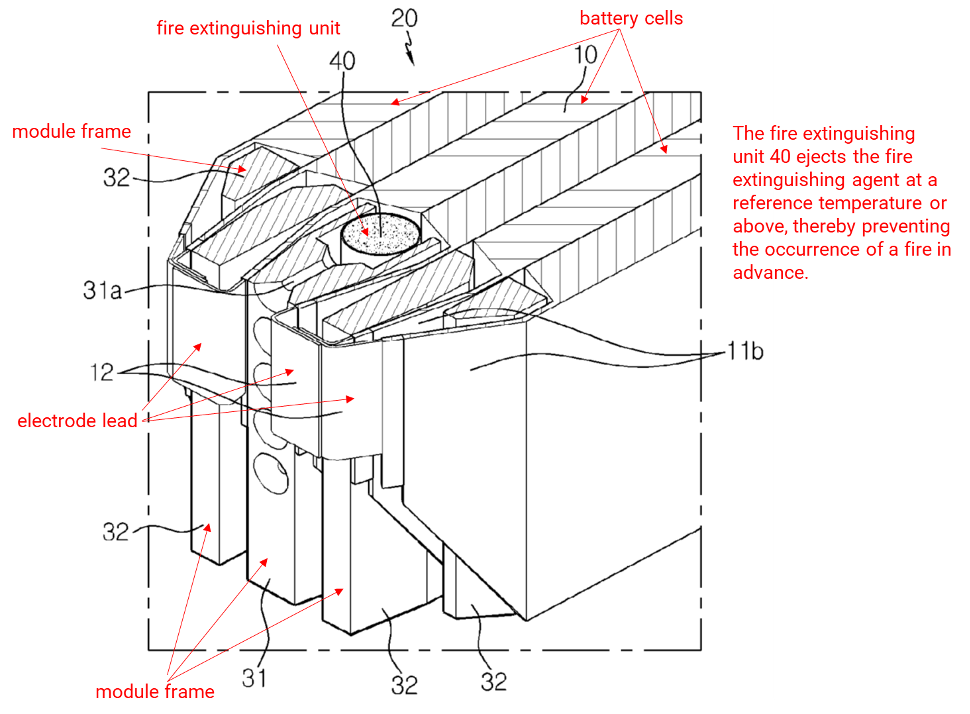

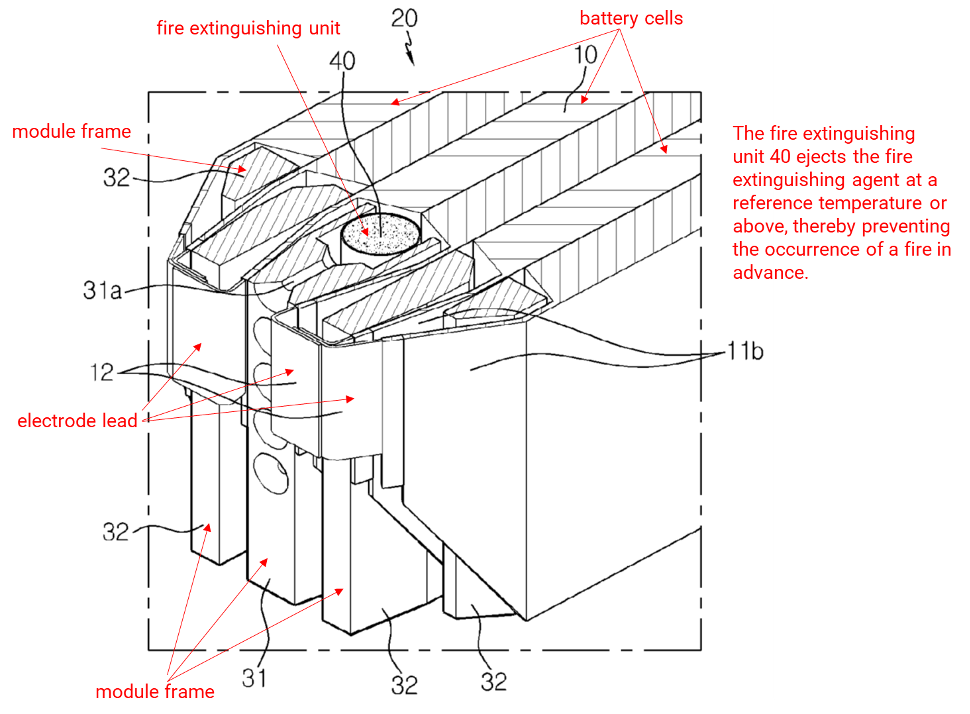

Protection mechanism – Fire extinguishing

In the previous article, fire extinguishing units can be disposed inside a battery cell. When the temperature of the cell exceeds a predetermined value, the fire extinguishing unit release fire extinguish power to stop the occurrence of thermal runaway. Similarly, battery modules may also include fire extinguishing mechanism. Taking LG Chem’s patent US10874889 as an example, as shown in Fig. 9, fire extinguishing units are accommodated in a module frame of battery packs. The fire extinguishing unit ejects fire extinguishing agent at a reference temperature or above, thereby preventing the occurrence of a fire.

Fig. 9 Drawing of LG Chem’s patent US10874889

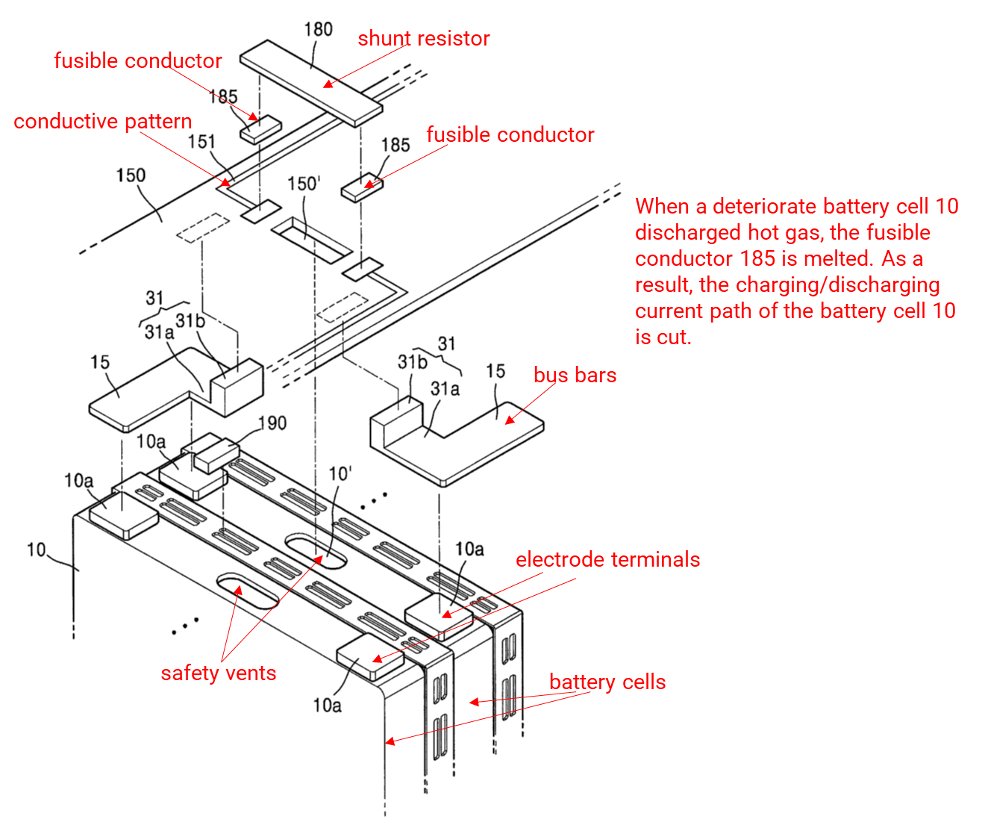

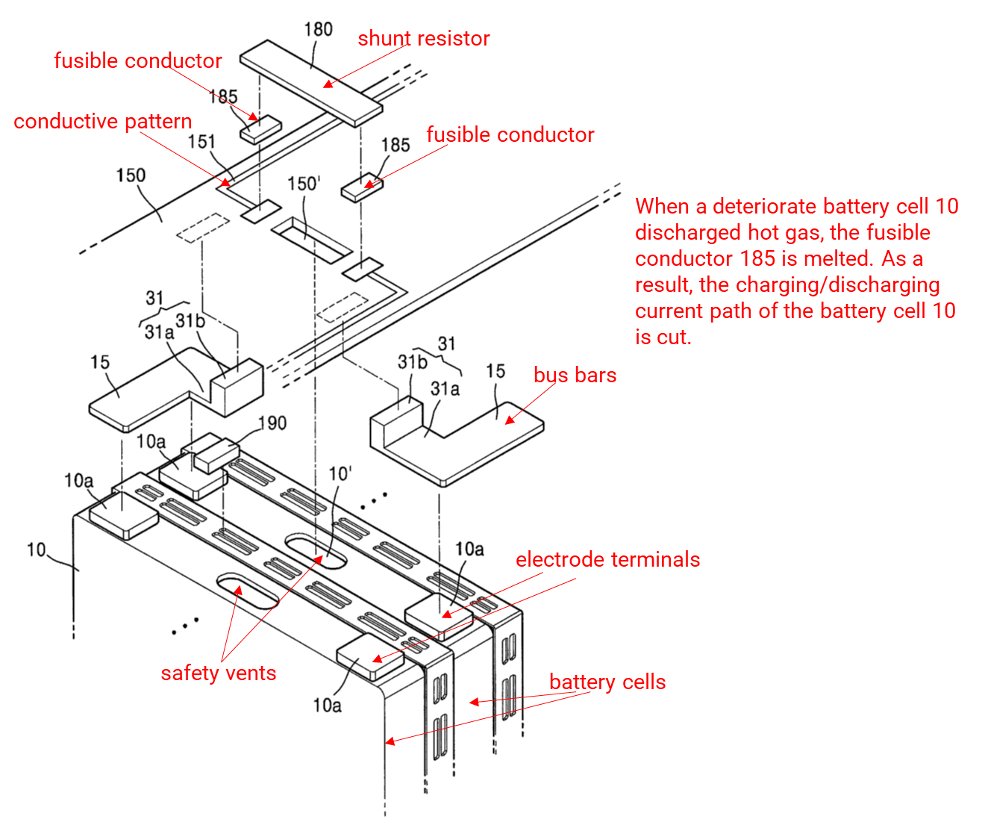

Protection mechanism – Cut-off protection

Charging or discharging batteries above threshold temperature causes thermal runaway. Disconnecting abnormal cells in a battery pack can avoid more damages. Taking Samsung SDI’s patent US10050315 as an example, as shown in Fig. 10. When a deteriorated battery cell discharges hot gas, a fusible conductor which connects to bus bars is melted. As a result, the charging/discharging path of the battery cell is cut.

Fig. 10 Drawing of Samsung SDI’s patent US10050315

In summary, for the design of battery modules, the risk of thermal runaway can be prevented or reduced by using cooling mechanisms, optimization of the module structure and employing various protection mechanisms. Besides cell improvement and module design, when using the battery module, it is also important to take care of thermal issues through battery management system (BMS). Our next article will develop in more detail BMS solutions for thermal runaway.

[1] Tesla Model S -

https://en.wikipedia.org/wiki/Tesla_Model_S

Author: Jean Chou

Taiwan Patent Attorney / Certified Valuation Analyst / Co-Chair of Business IP Management Committee, TWPAA / Vice President of

WISPRO Technology Consulting Corporation

Email: jeanchou@wispro.com

![[Expert Views] How Tesla Explores its Patent Assets](https://www.mih-ev.org/s3/mih%2Fwp-content%2Fuploads%2F2023%2F01%2FWispro-Expert-Views.png)